Certified CNC Machining ISO 9001 – Quality Control

Nasza certyfikowana obróbka CNC ISO 9001 gwarantuje pełną identyfikowalność i powtarzalność każdej partii detali. Our certified CNC machining under ISO 9001 ensures full traceability and repeatability of each production batch. CNC quality control is carried out from the incoming material to final 3D measurements in the CMM laboratory. The integrated SPC system records data in real time, allowing immediate response to the slightest deviations.

Quality and Production Process Control

At APJ Sikora, we place special emphasis on the quality of every stage of production. We implement a quality management system based on ISO 9001:2015, and all components are inspected using modern measurement techniques.

Thanks to our in-house laboratory and digital supervision of measurement results, we ensure full compliance with technical documentation and high process repeatability.

Learn more about our machine park →

Measurement Laboratory

The quality of every component is overseen by our modern CNC measurement laboratory, equipped with precision instruments from leading manufacturers:

- Zeiss

- Mitutoyo

- Mahr

- Keyence

Thanks to our internal metrology capabilities, we can perform dimensional verification, geometry and roughness evaluation, and repeatability checks – both under production and laboratory conditions.

All measurements are conducted in accordance with current industry standards and customer documentation, ensuring full compliance of the final product with technical requirements.

Main Metrology Equipment

Our laboratory is equipped with modern machines and metrology systems that provide full CNC quality control – precise measurement of details, including geometry inspection, contour analysis, surface roughness measurement, and other drawing-specified features.

These devices ensure dimensional compliance with technical documentation and provide full quality support in serial and small-scale production.

Our equipment includes:

- 3D Coordinate Measuring Machine with 5-axis probe head

- Digital Optical Comparator

- Contour Measuring Instrument

- Digital Measuring Microscope

- Surface Roughness Tester

- Shop-Floor Coordinate Measuring Machine

- Inspection Microscope

Manual Measuring Instruments

For daily quality control, we also use handheld measuring tools that enable fast and precise verification of component parameters.

Their versatility and reliability make them suitable for single-part, in-process, and final inspections – both during production and at the final quality-control stage.

We use:

- 3-Point Bore Gauges (trigger-type)

- Air Gauges

- Calipers

- Digital and Analog Micrometers

- Digital Snap Gauge

- Height Gauges

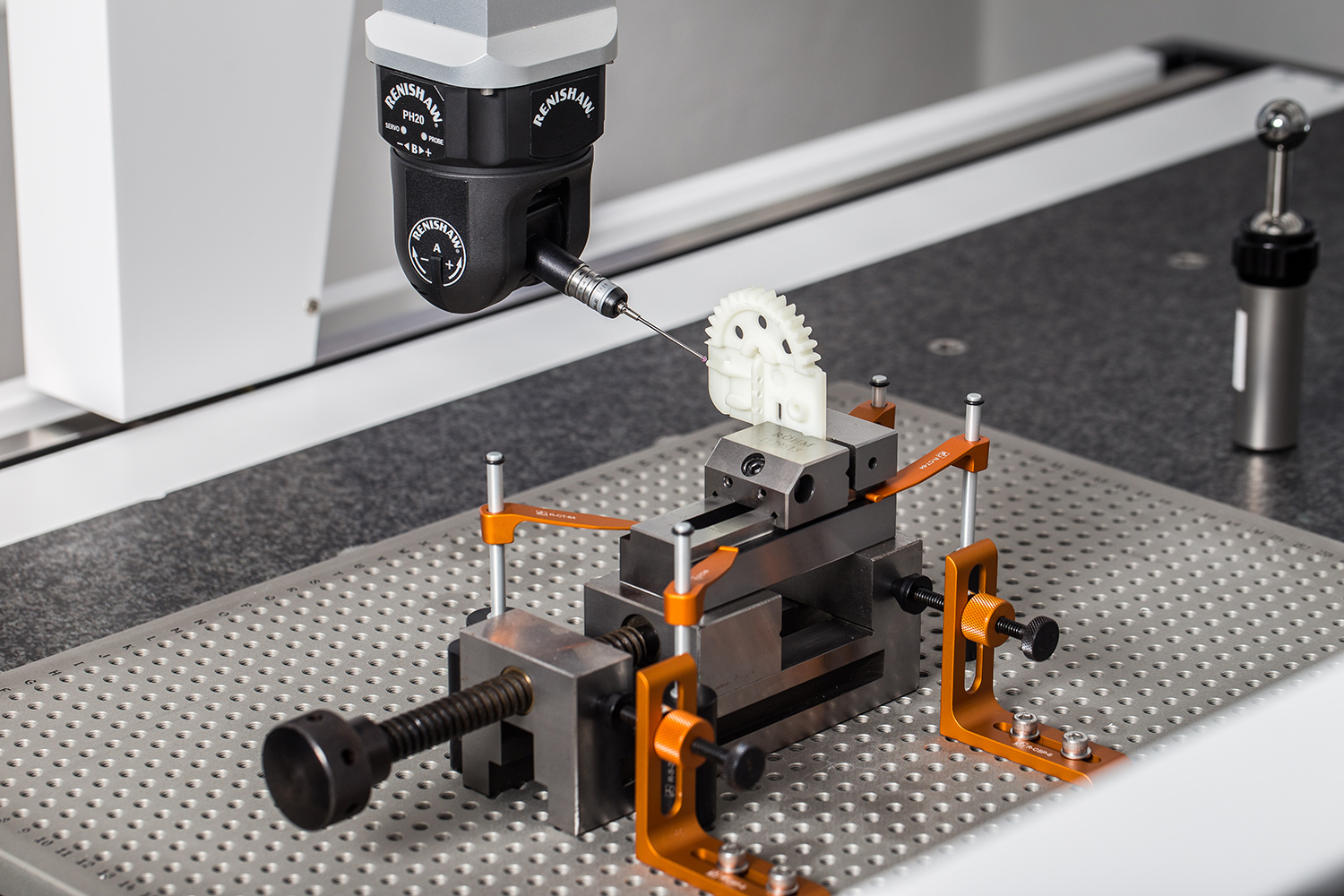

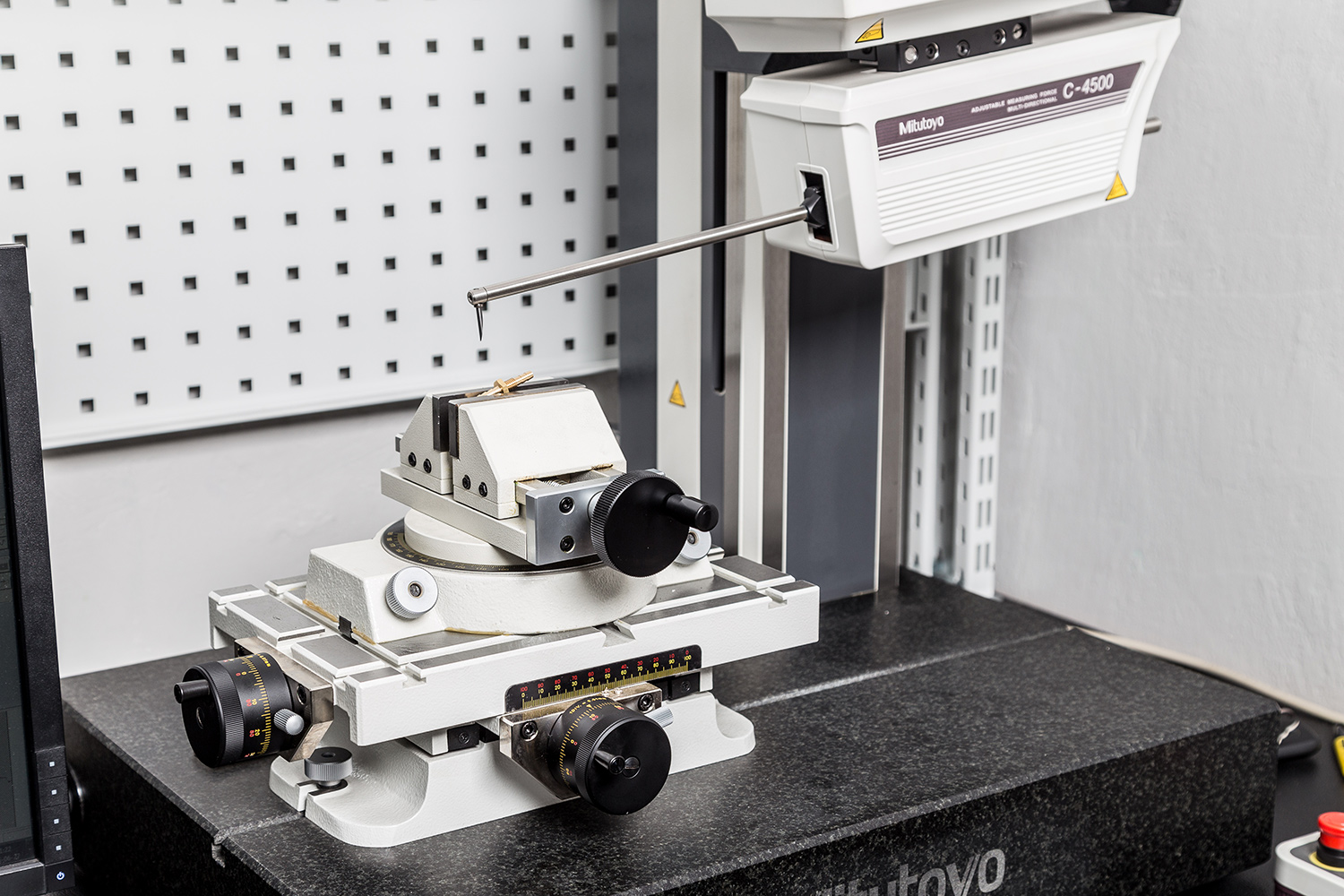

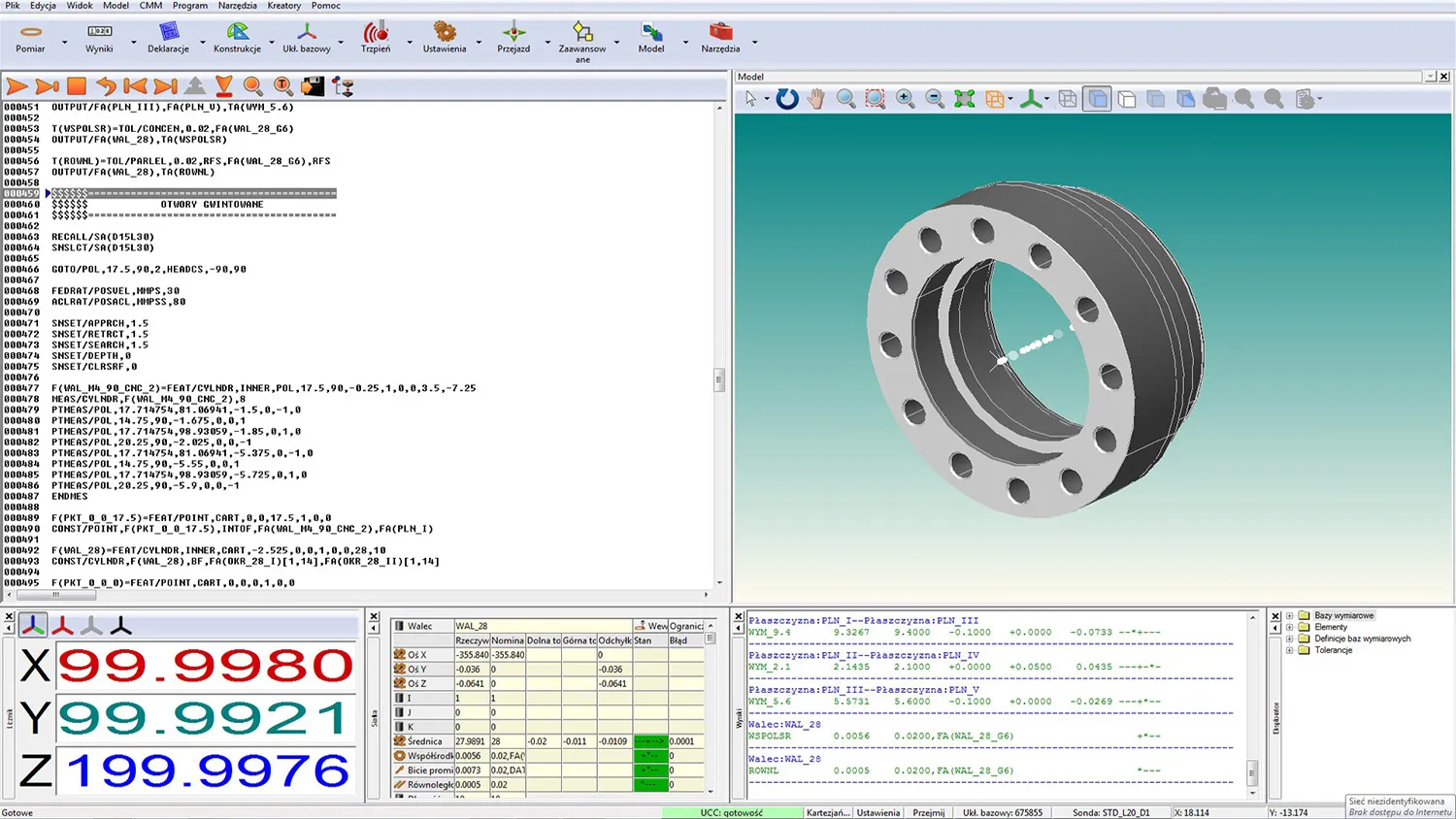

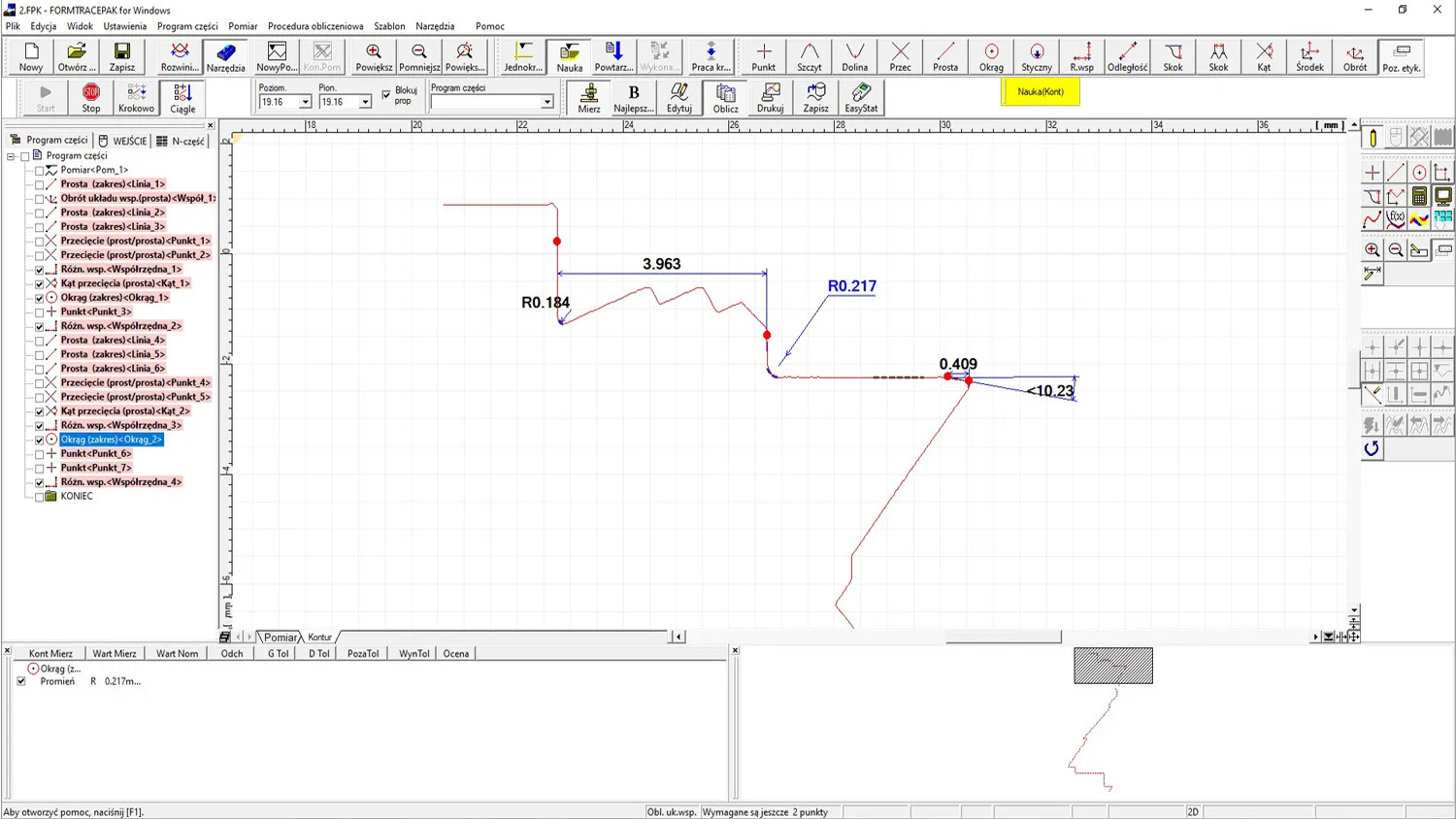

Gallery – Quality Control in Practice

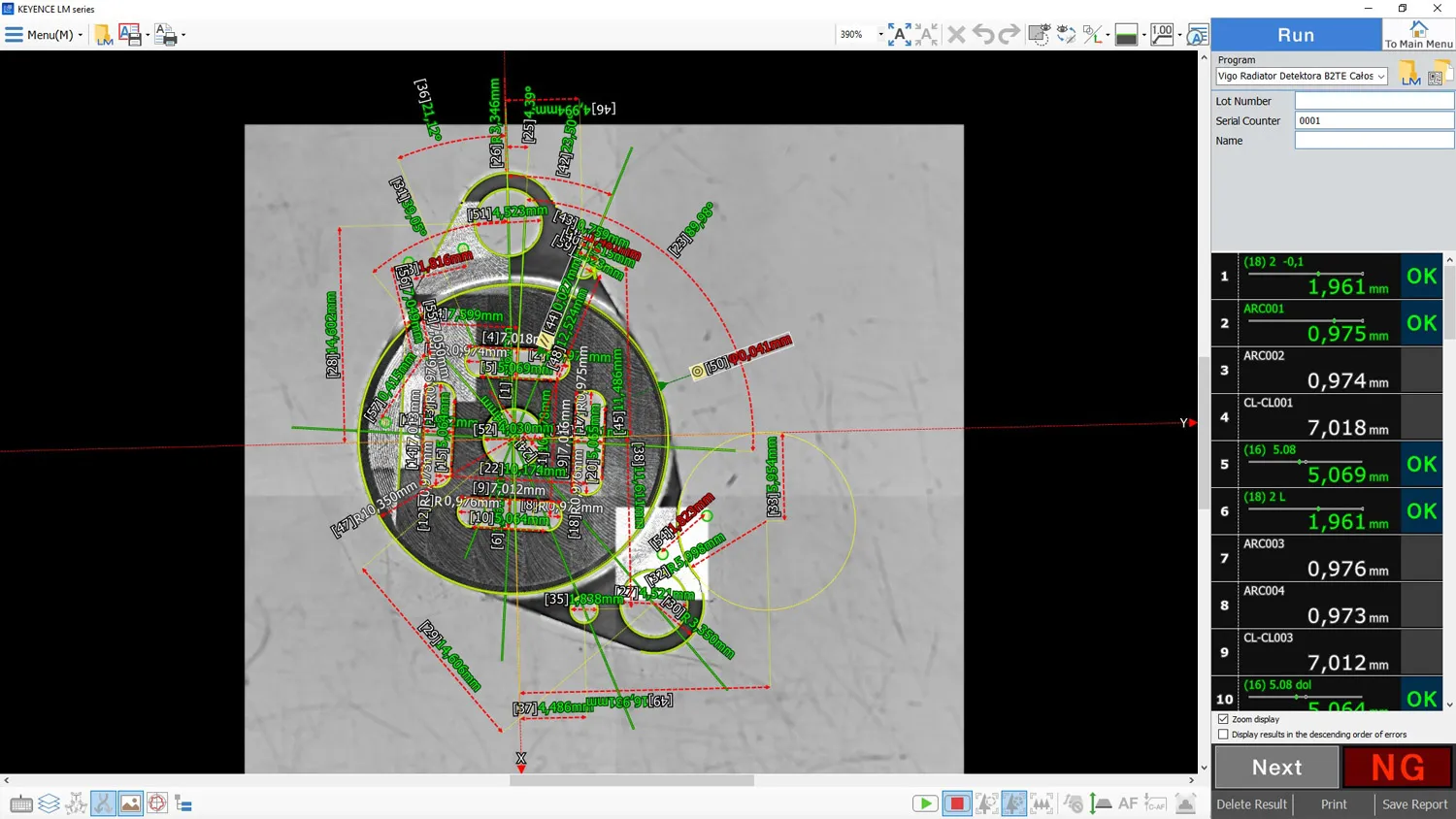

Below is a selection of images illustrating the process of parts measurement, using coordinate measuring machines (CMMs), microscopes, and digital optical comparators. These photos show the practical application of inspection techniques – from geometry and contour analysis, through surface roughness measurement, to verifying dimensional conformity with technical drawings.

- Coordinate Measuring Machine (CMM) with 5-axis probe head

- Shop-Floor Coordinate Measuring Machine

- Contour Measuring Instrument – CNC profilometer

- Part measurement using a Coordinate Measuring Machine (CMM)

- Contour analysis of a technical component on a CNC profilometer

- Dimensional and GD&T inspection using a Digital Optical Comparator

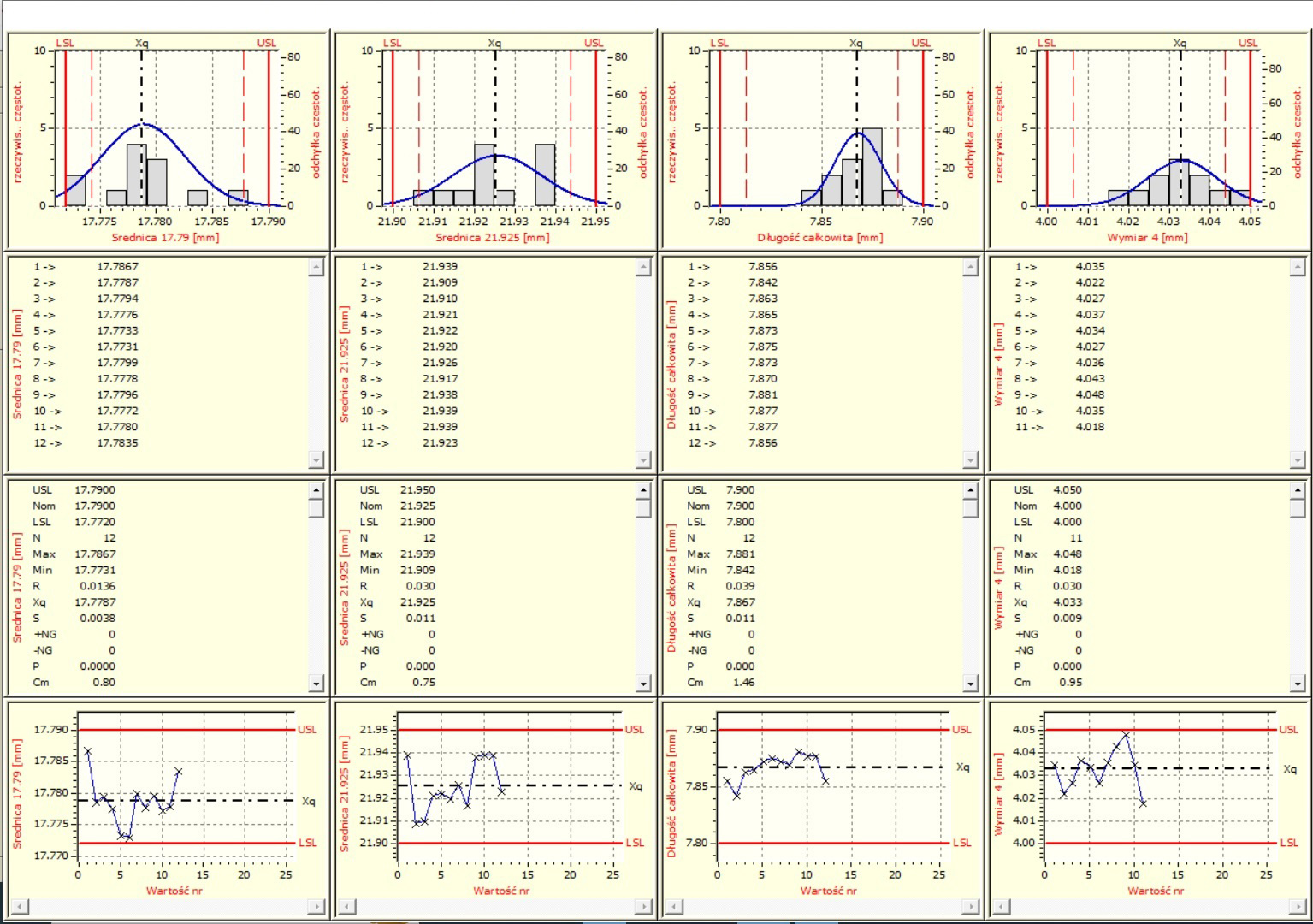

Measurement Management System – Digital Monitoring and SPC Reports

Our laboratory is supported by an advanced digital measurement management system that enables real-time quality monitoring.

The software archives data from measuring machines and analyzes it using statistical quality indicators such as Cp, Cpk, Pp, and Ppk, generating reports tailored to customer requirements.

SPC – Statistical Process Control

SPC (Statistical Process Control) is a method of supervising production processes using measurement data analysis.

Widely used in modern CNC machining, it allows for early detection of deviations from nominal values, increasing process stability, repeatability, and efficiency in serial production.

SPC also provides a solid foundation for quality reporting and meeting specific customer requirements.

SPC – Advanced Quality Control in CNC Machining

Our quality control system is not limited to individual measurements – it's a comprehensive system ensuring full reliability and repeatability of each component.

Below are the key pillars of our SPC system, which guarantee consistent oversight and the highest product quality:

- Comprehensive monitoring of dimensional parameters via CMMs and optical projectors, ensuring top accuracy

- Real-time Statistical Process Control (SPC) with automatic alerts on deviations

- Archiving and traceability – full measurement documentation available in electronic control charts and ISO reports

- Continuous improvement – process trend analysis, Cp/Cpk and Pp/Ppk indicators, supporting process optimization

As a result, our customers receive not only precise parts but also full support via a certified quality control system compliant with industry standards.

Explore our CNC turning services →

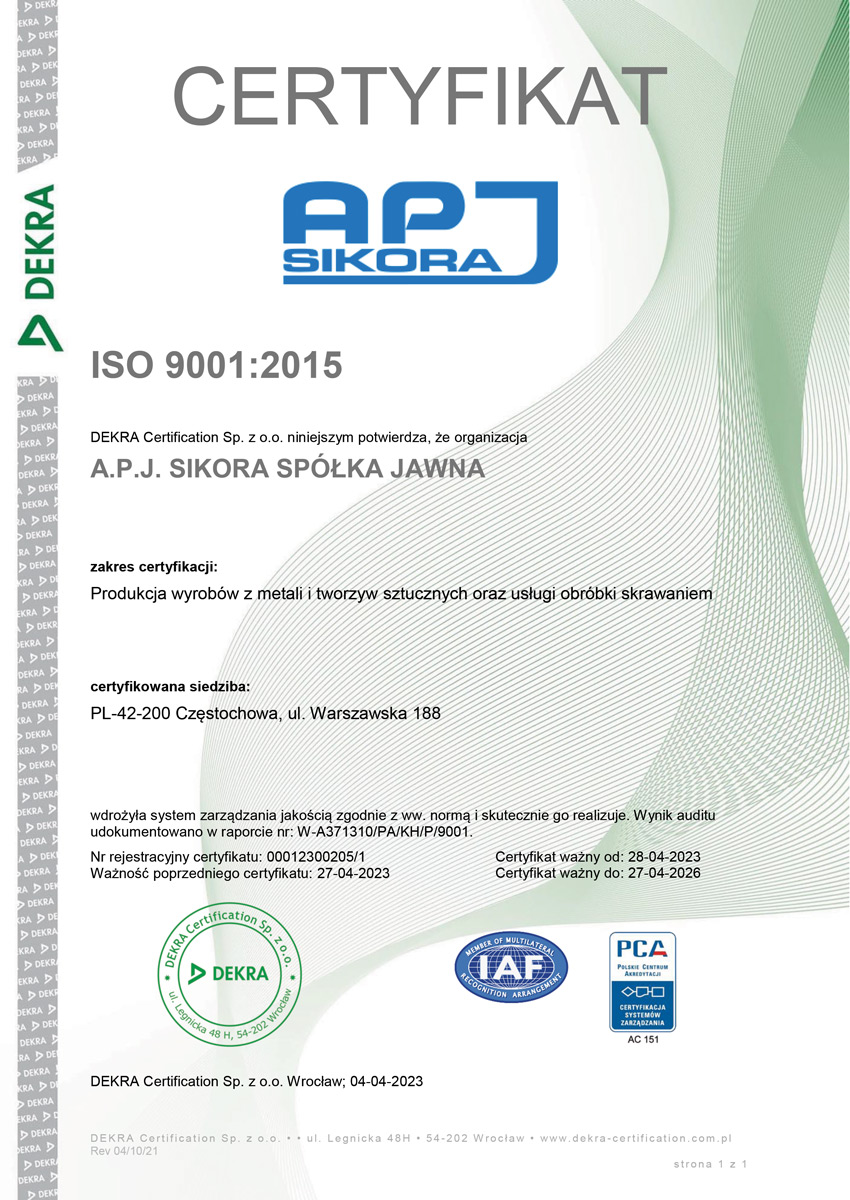

ISO 9001:2015 Quality Certificate

Our ISO 9001:2015 certificate confirms that our production processes and quality management system meet international standards.

We guarantee repeatable production parameters, compliance with technical documentation, and full control over the production cycle – from raw material to finished component.

Download the certificate in .pdf

ISO 9001:2015 – official standard reference (www.iso.org)

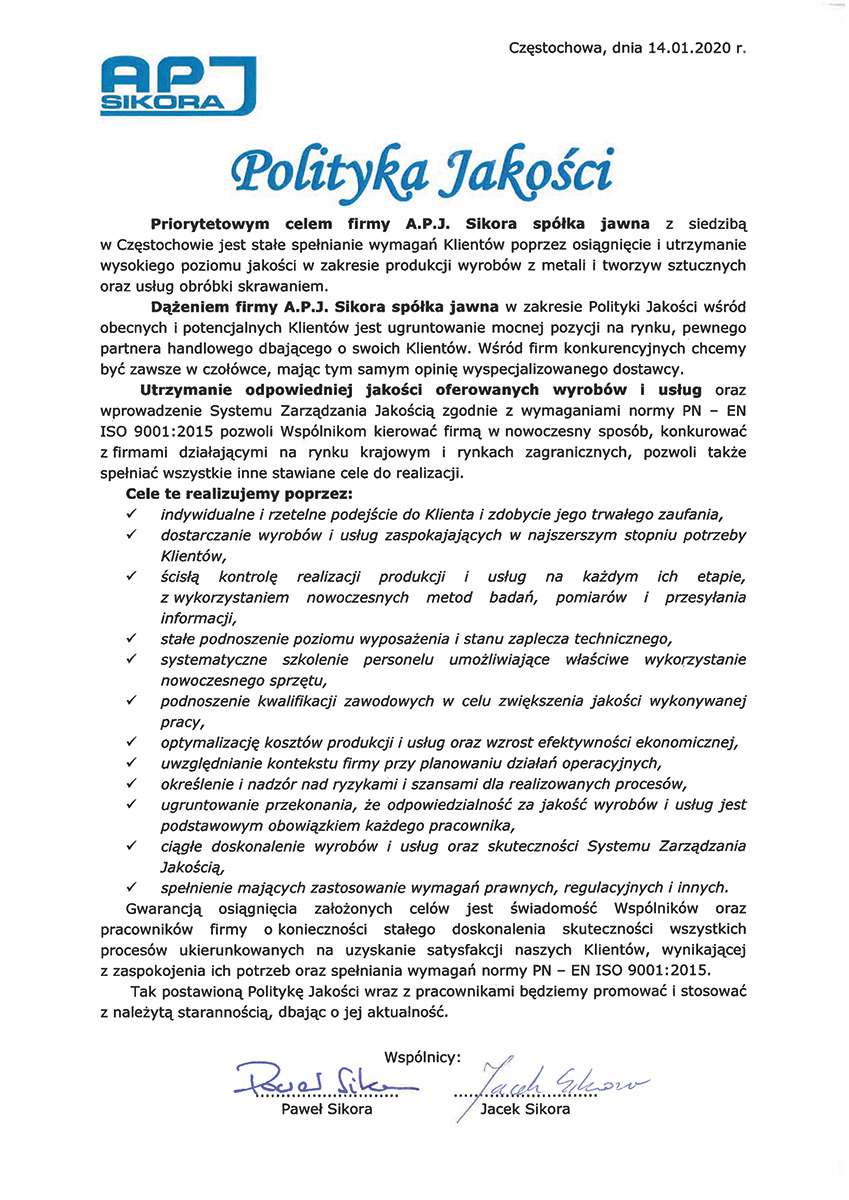

Quality Policy

At the heart of our quality policy is the goal of complete customer satisfaction. We implement this through:

- Timely deliveries and manufacturing of products in accordance with quality requirements

- An experienced team and continuous professional development

- Ongoing improvement of the work environment to enhance product quality and process repeatability

This policy is the foundation of our company’s further development and long-term partnerships with demanding customers.

Do You Have Questions About Quality or Documentation?

Contact us – we’ll be happy to show you how the quality control process works at APJ Sikora.

We will prepare a quotation and documentation in accordance with ISO 9001:2015, PPAP, or VDA-4.