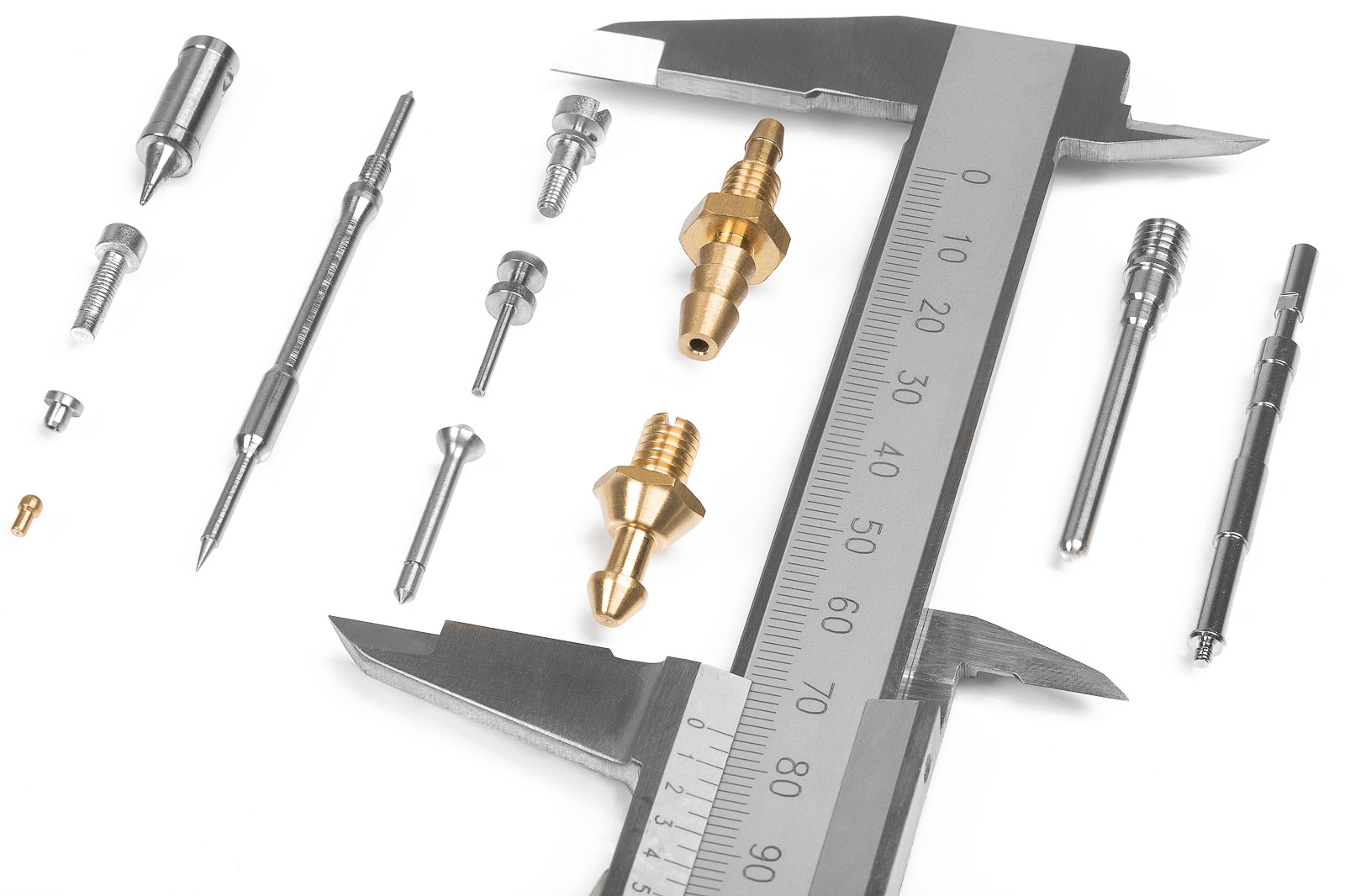

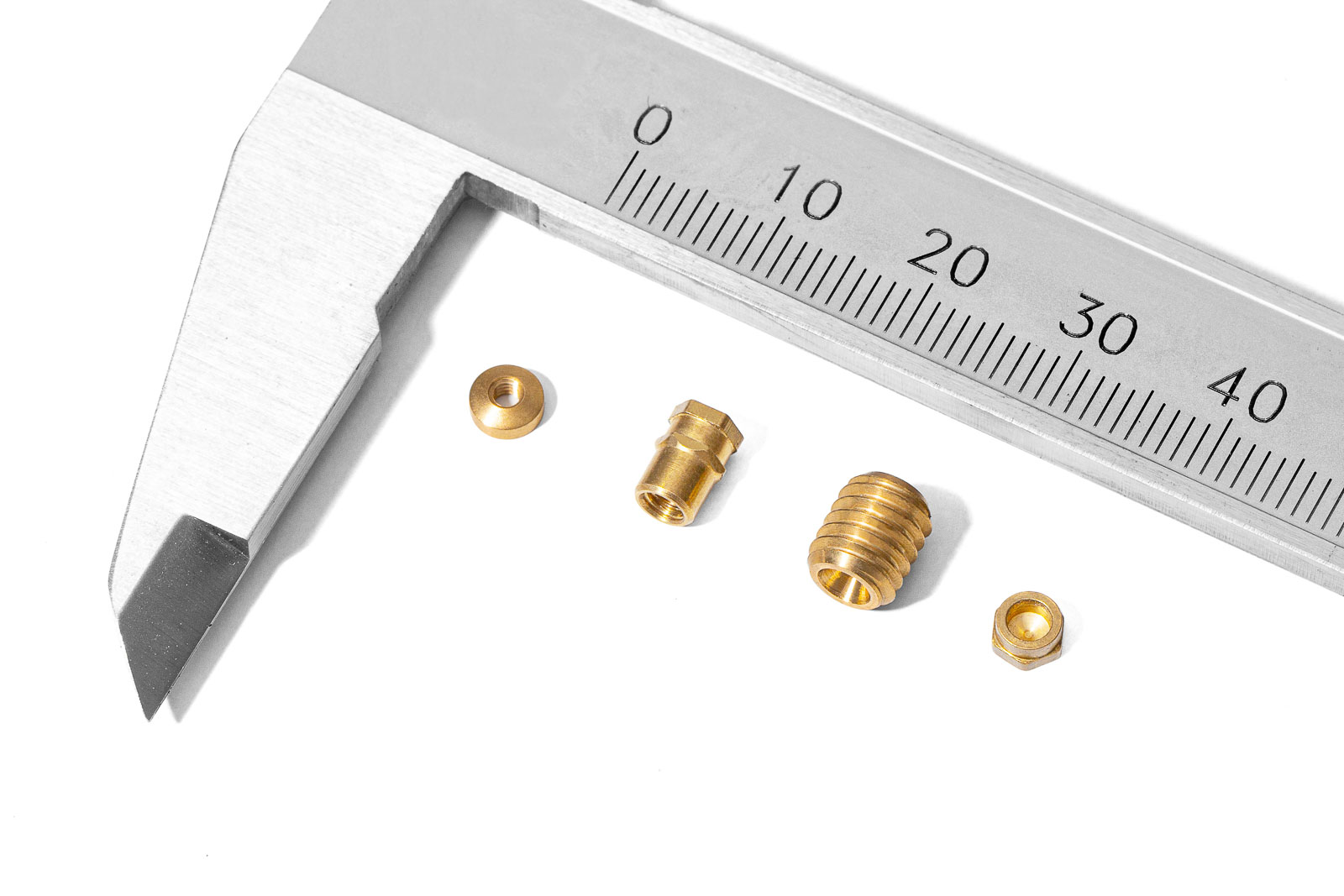

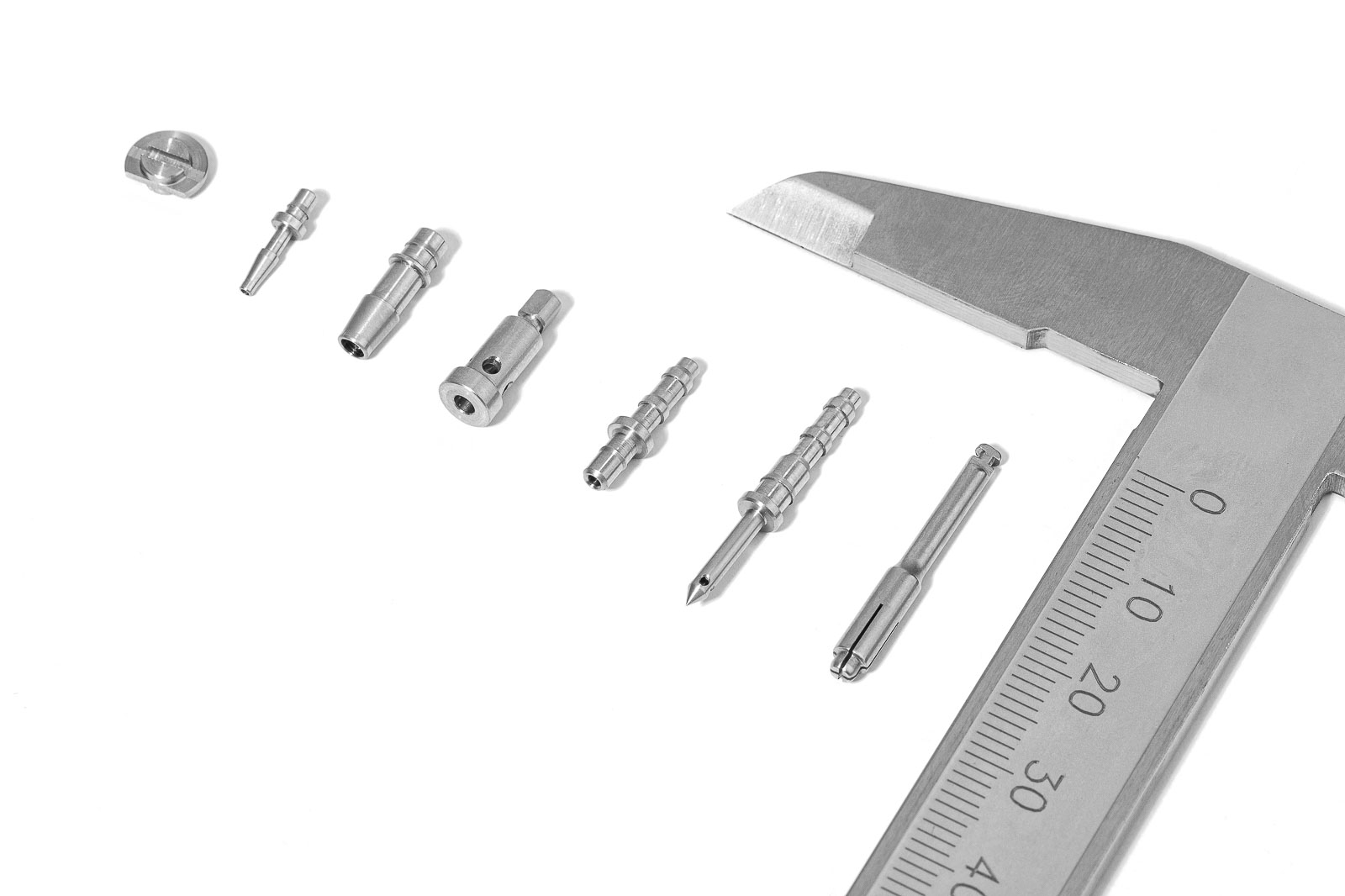

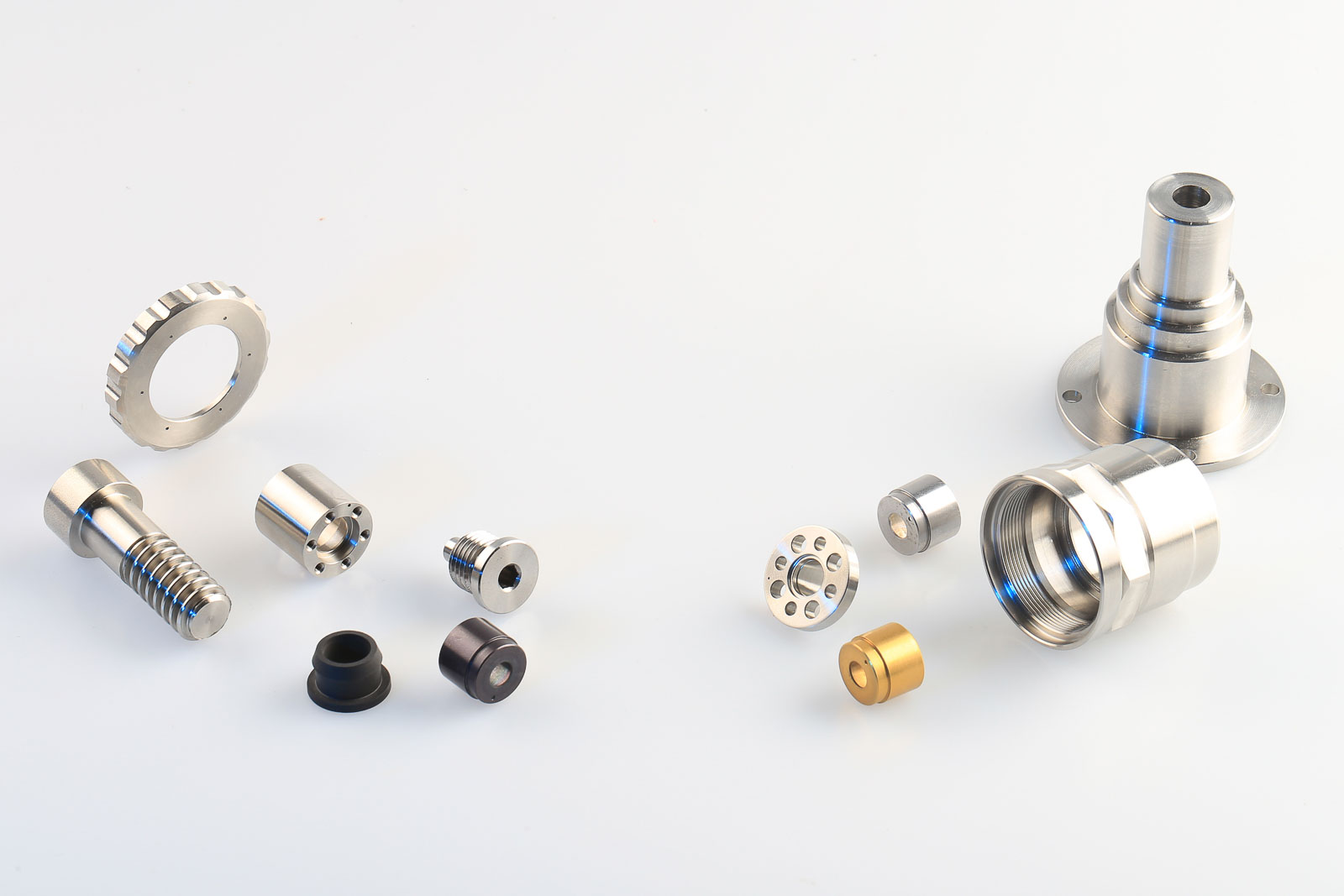

CNC Parts Gallery – Precision Machining, Milling, and Turning

ZWe invite you to explore the APJ Sikora gallery. We showcase CNC-turned parts and components created through CNC milling. Our precision CNC machining, carried out at our CNC facility in Częstochowa, demonstrates production capabilities ranging from prototypes to series of up to 50,000 pieces.

CNC Parts Gallery – Our Projects

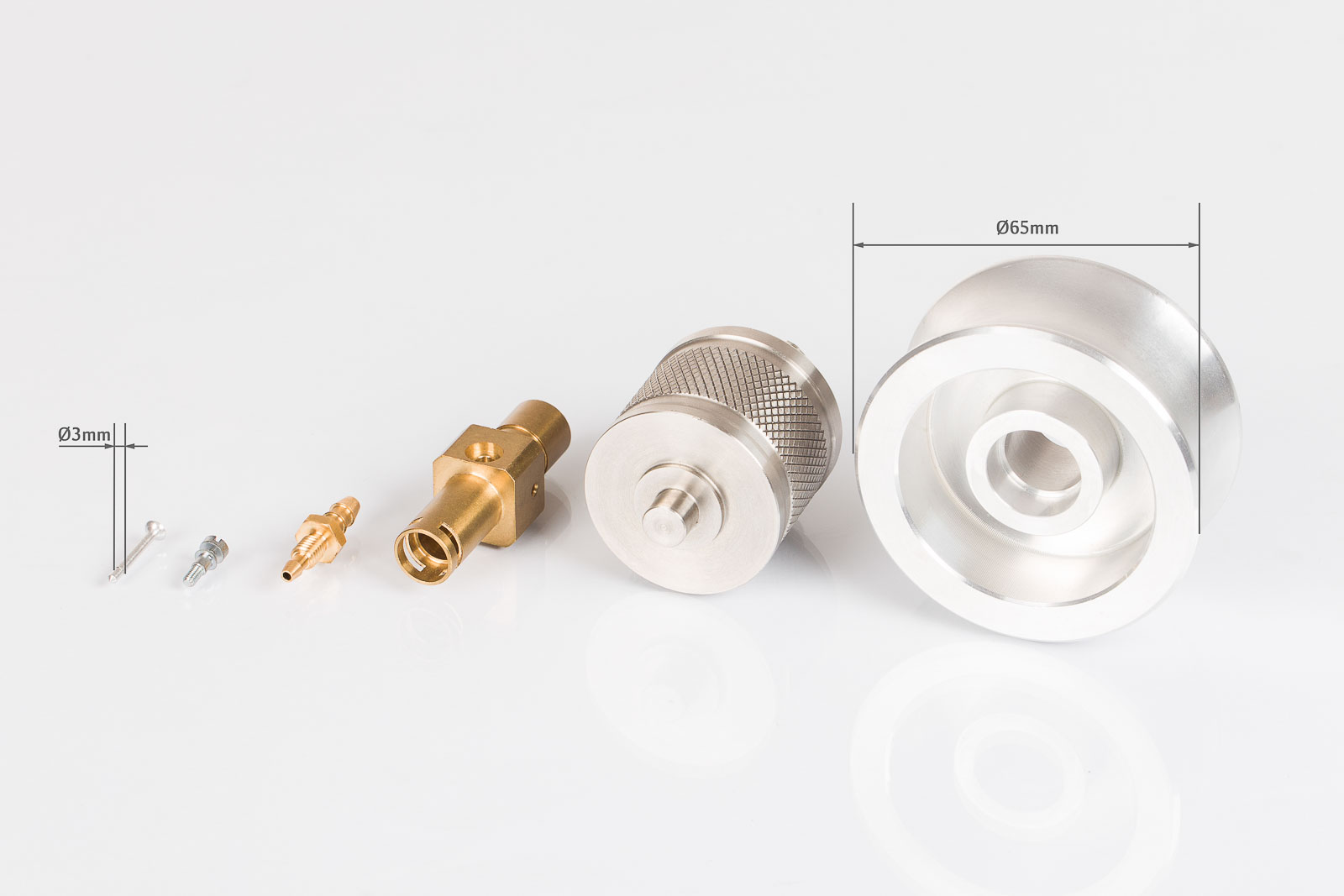

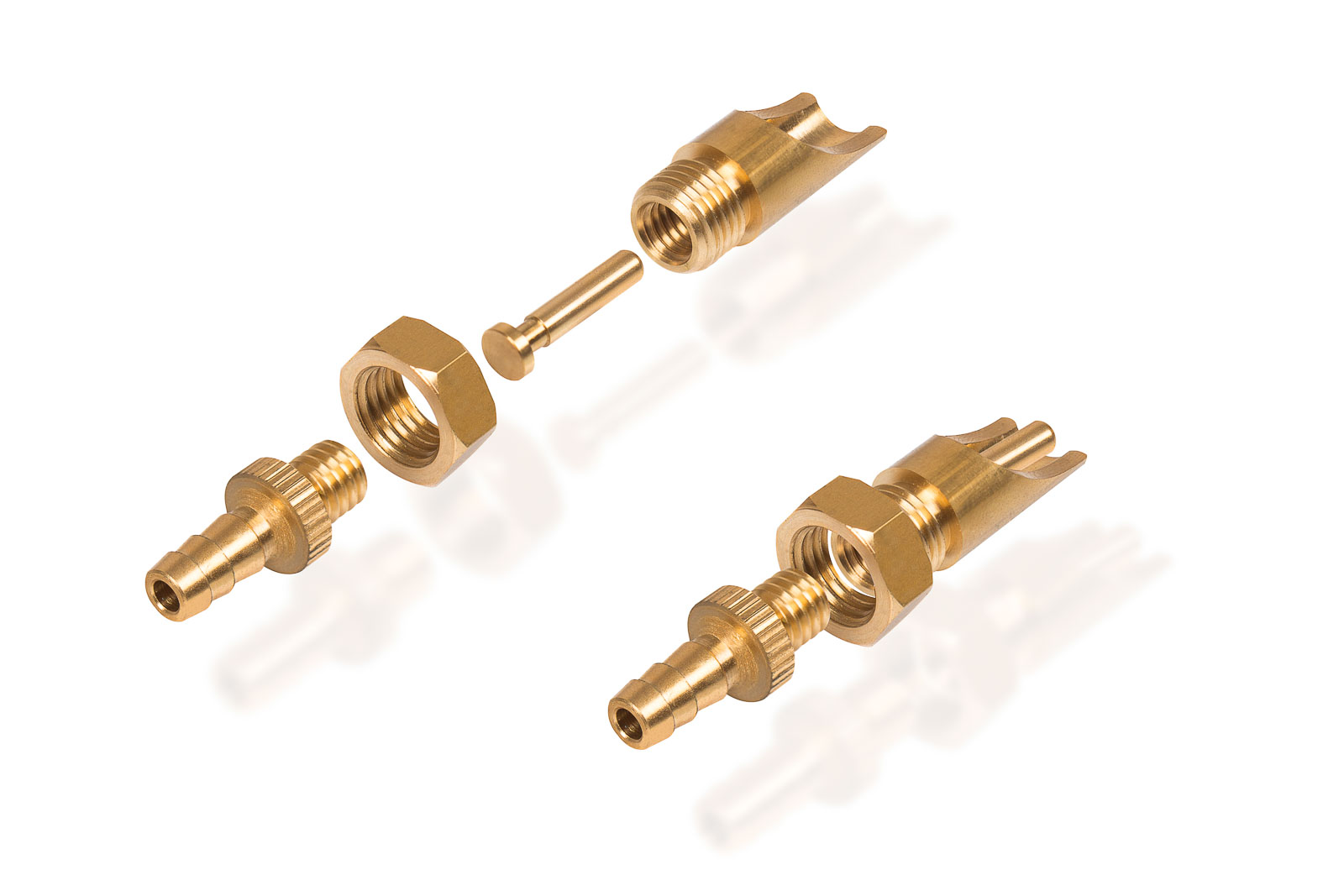

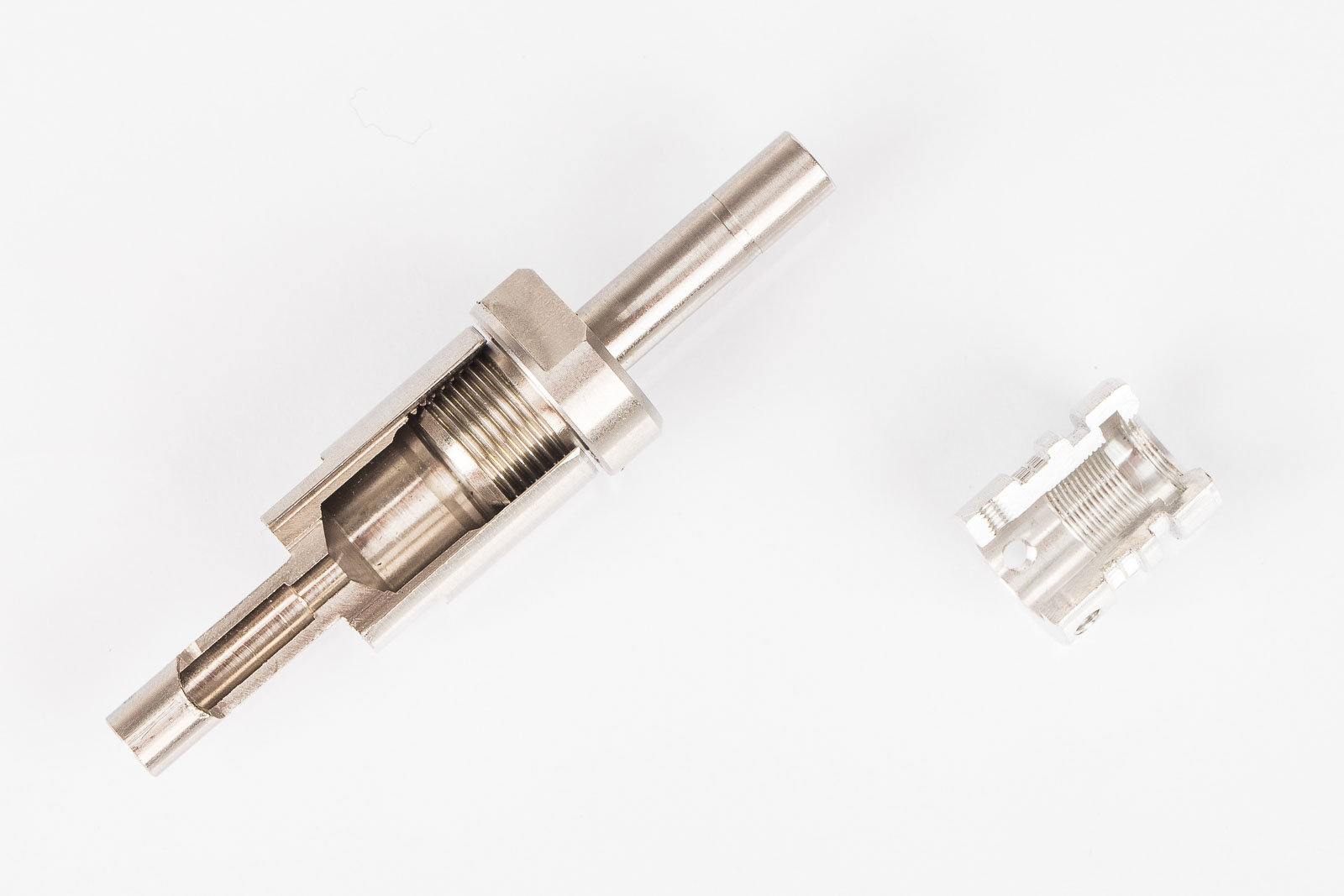

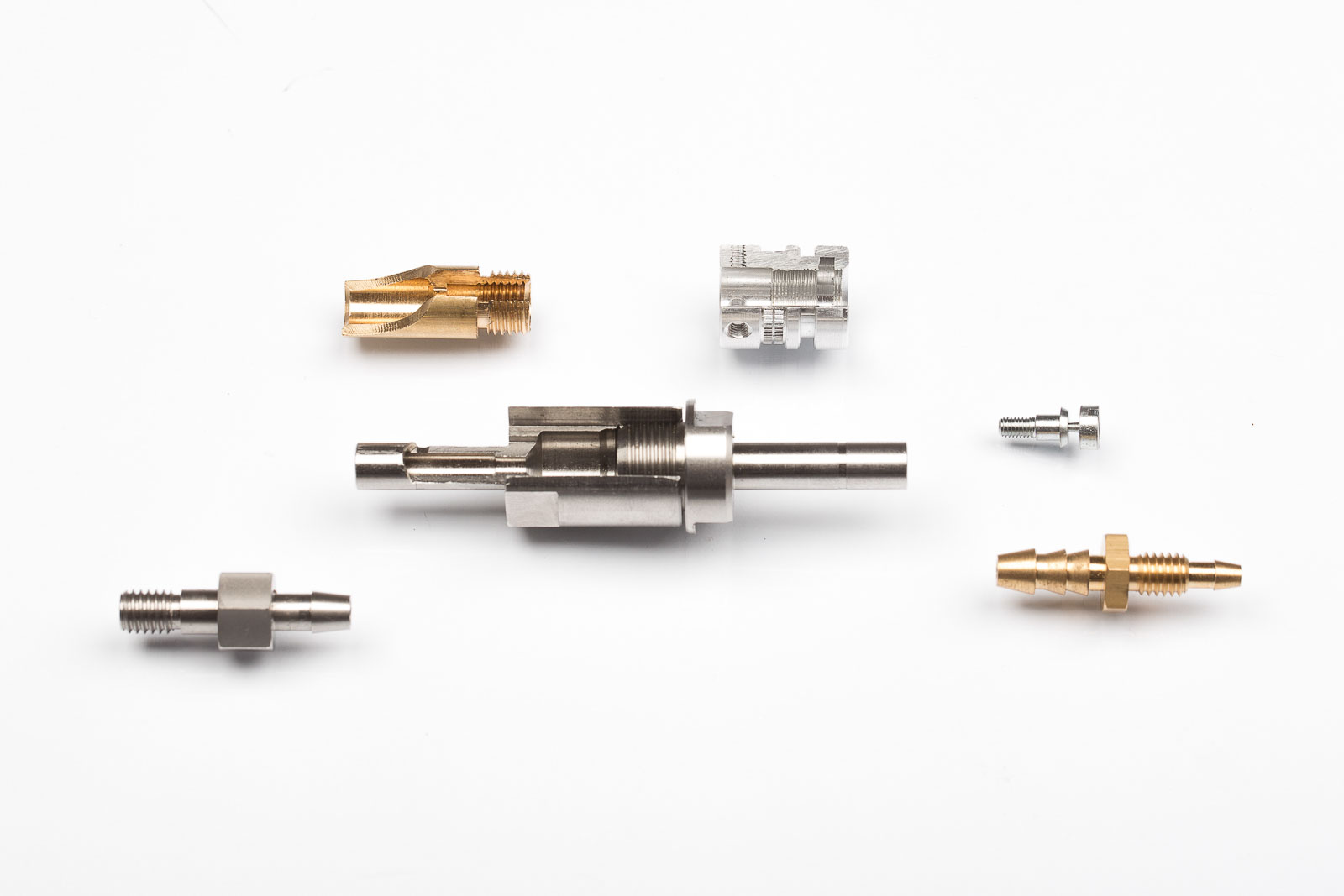

Explore selected components manufactured using CNC turning technology.

We present sample parts produced by APJ Sikora – from simple components to more technically complex precision parts.

The photos show excerpts from our series and small-batch production, carried out on automatic lathes and verified in our measurement laboratory.

Would you like to produce a similar component or implement your own project? Contact us!

Interested in Our Projects?

We will be happy to prepare a quote tailored to your project – from idea to finished part. Submit an inquiry or request an estimate.

See Why We Are a CNC Expert from Częstochowa

From a craft workshop to a leader in precision CNC machining – learn about the story behind the quality of APJ Sikora components.

We operate locally (CNC Częstochowa), but our precision is appreciated by clients across Poland, Europe, and USA.

Each project is approached individually, with a strong focus on understanding the technical and quality requirements of our customers.

That’s why APJ Sikora is a synonym for precision, tradition, and modern CNC technology.

Our Offer – Comprehensive and Precise CNC Machining

We specialize in the production of CNC turned parts, from prototypes to large series – always maintaining the highest quality and precision of execution.

We handle even the most demanding CNC projects, in full accordance with your technical documentation. We offer technical support and consulting in the selection of materials and manufacturing methods, ensuring full support from design to final CNC part.

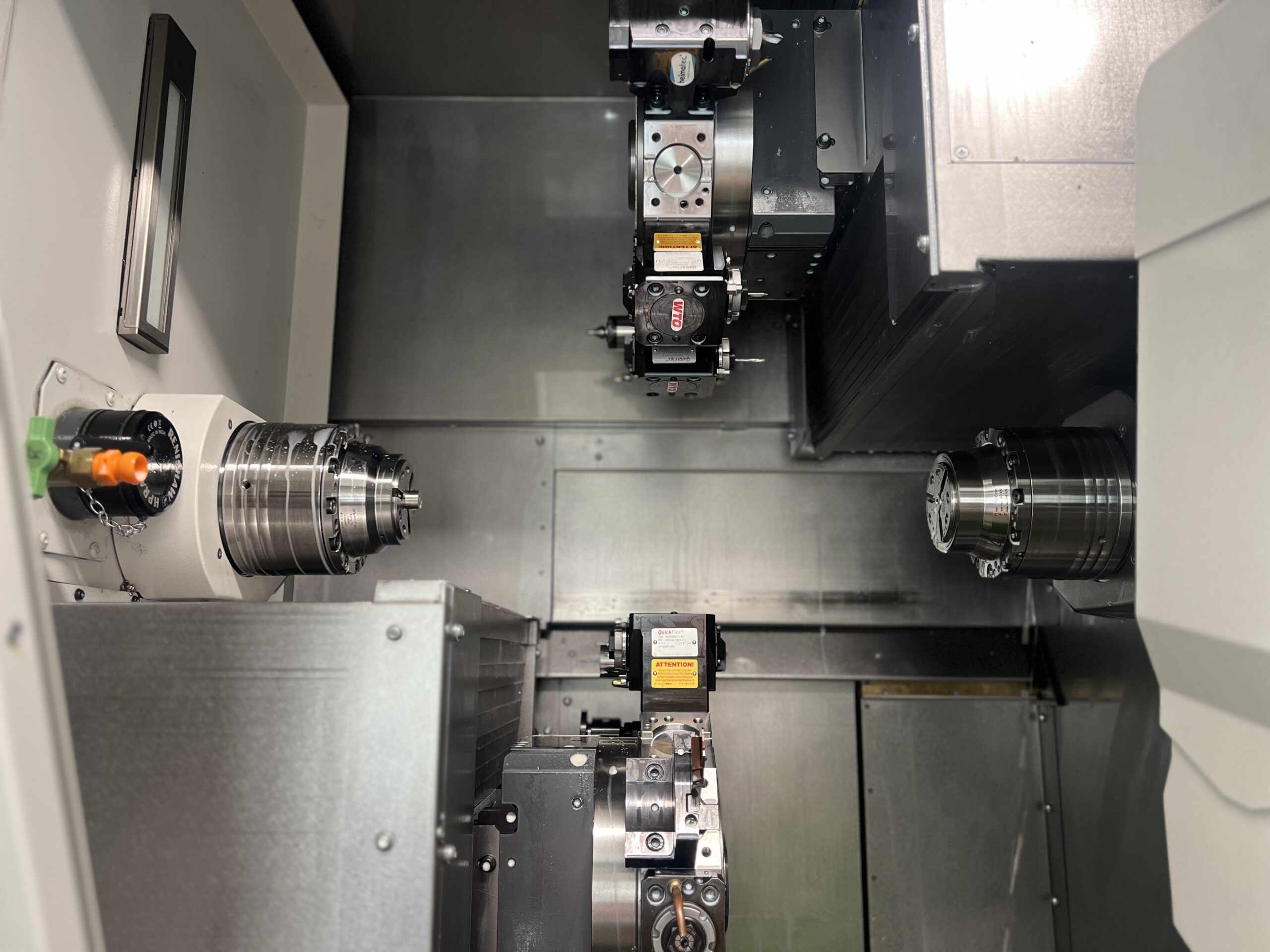

Discover Our Modern CNC Machine Park

We operate advanced CNC milling centers and automatic lathes for CNC turned parts, enabling us to meet even the most demanding production requirements.

Continuous modernization allows us to provide top quality standards and short lead times.

Our machine park guarantees precision, production speed, and technological flexibility – appreciated by our clients.

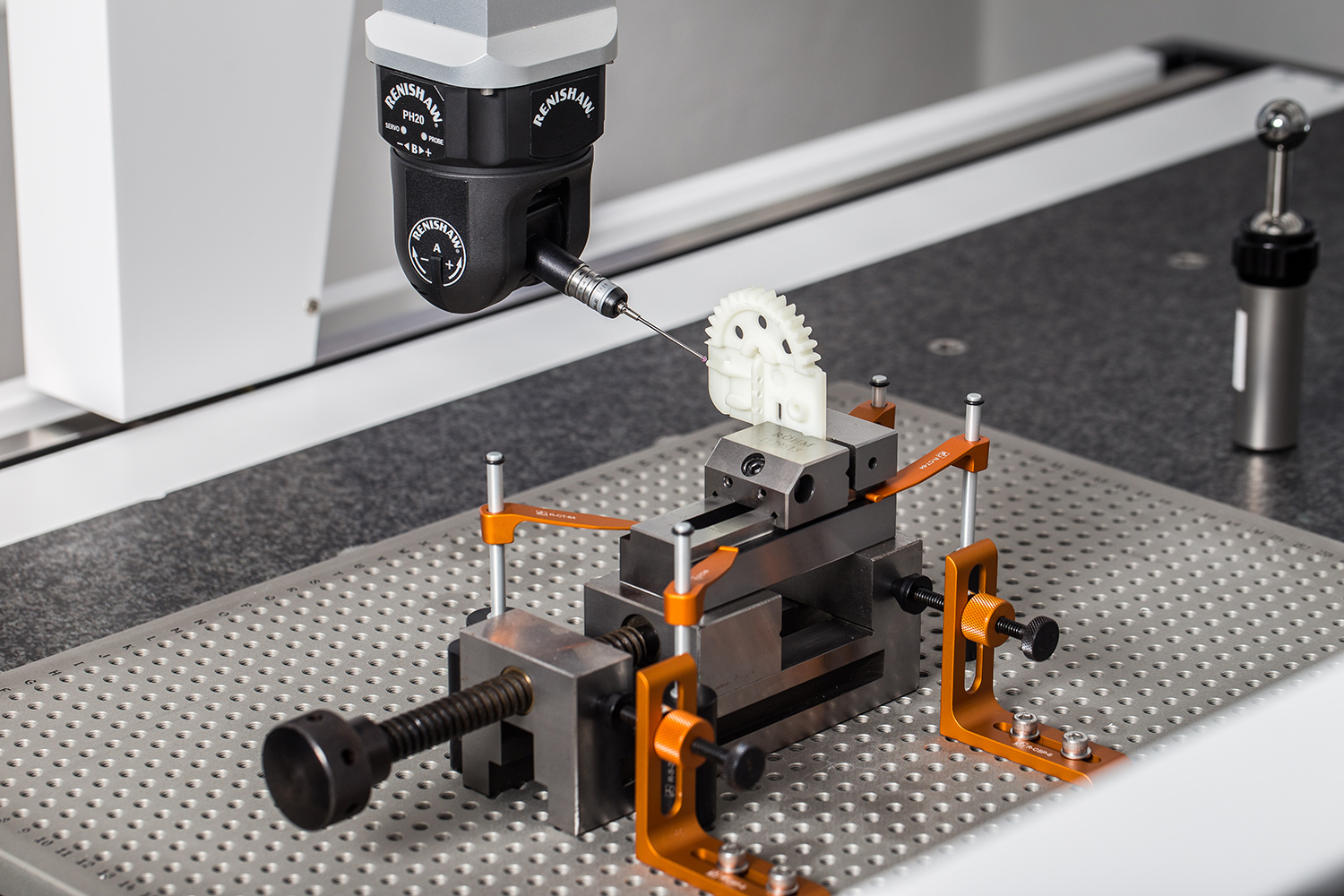

Quality Control – the Foundation of Our Precision

Our in-house metrology laboratory, ISO 9001 certification, and strict inspection procedures ensure that our CNC milling and turning always meet the highest technical standards.

Every part is thoroughly checked to match your requirements.

With digital process monitoring and advanced measuring equipment, we guarantee full repeatability of every production batch.

Photography by Blik Studio