CNC Turning and Milling Services – APJ Sikora

Comprehensive CNC services in precision machining of metals and plastics from Ø1 mm to Ø65 mm. We carry out small-batch and series production of CNC components in accordance with ISO 9001:2015.

Turned Parts Production – Precision CNC Machining from Ø1 mm to Ø65 mm

APJ Sikora specializes in CNC turning using sliding-head lathes and CNC turning centers with bar feeders. We machine carbon steel, alloy steel (including stainless), copper alloys, brass, and aluminum.

As a CNC machining provider based in Poland, Częstochowa, we supply components to customers throughout Poland, ensuring short lead times and production repeatability. The selection of technology and tools is always tailored to the technical requirements and expected accuracy.

CNC Milling – Precision for Complex Components

Our CNC lathes with driven tools combine turning and CNC milling in a single clamping setup. This allows us to produce pockets, channels, angled holes, and various planes without transferring the part to another workstation, shortening cycle time and eliminating repositioning errors.

In series production, we maintain stable cycle times, while for small batches we ensure the same level of accuracy through precise tool setup and optimized cutting parameters.

We machine alloy steels, stainless steels, aluminum, brass, and engineering plastics such as POM-C and PEEK, making our CNC services suitable for industries such as aerospace, hydraulics, and medical.

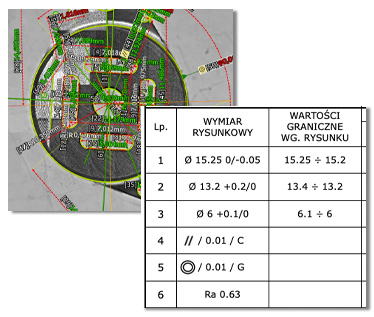

Production Capabilities – Geometric Tolerances and Dimensional Accuracy in CNC Turning

Our technological and metrology resources allow us to produce parts with high repeatability and compliance with geometric and dimensional tolerances.

We apply modern methods of form and position error control, in accordance with the technical drawing and customer documentation.

Achievable CNC Machining Accuracy

The table below presents the production precision and tolerances we guarantee in repeatable CNC part manufacturing.

Our tolerances are defined in accordance with the ISO standards:

| Production capabilities we can achieve with high repeatability | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Tolerance Type |

Internal diameter |

External diameter |

Position error |

Runout |

Flatness |

Parallelism |

Coaxiality |

Perpendicularity |

|

Tolerance Range [mm] |

0.01 – 0.02 mm 0.0004 – 0.0008 in |

0.006 – 0.01 mm 0.00025 – 0.0004 in |

0.03 mm 0.0012 in |

0.015 – 0.02 mm 0.0006 – 0.0008 in |

0.015 – 0.02 mm 0.0006 – 0.0008 in |

0.01 – 0.02 mm 0.0004 – 0.0008 in |

0.02 mm 0.0008 in |

0.02 mm 0.0008 in |

What Materials Do We Machine? Example Alloys and Grades

Our CNC part production covers a wide range of materials, as specified in the customer’s technical documentation. We machine structural and stainless steels, non-ferrous metal alloys, and plastics.

Ensuring compliance of the final element with the geometric parameters, tolerances and quality requirements contained in the technical drawing.

Free-cutting steels:

- 1.0715 – (A10X, 11Smn30)

- 1.0718 – (11SMnPb30)

Carbon steels:

- 1.0038 – (ST3S, S235JRG2)

- 1.0045 – (18G2A, S355JR)

- 1.0503 – (C45)

Soft-magnetic low-carbon iron: ARMCO (04J)

Alloy steels:

- 1.7139 – (16MnCrSPb5)

- 1.7131 – (16HG , 16MnCrS5)

- 1.7142 – (16MnCrPb5)

- 1.7225 – (40HM , 42CrMo4)

Martensitic stainless steels:

- 1.4006 – (1H13, X12Cr13)

- 1.4021 – (2H13, X20Cr13)

- 1.4034 – (4H13, X46Cr13)

Austenitic / acid-resistant stainless steels:

- 1.4301 – (AISI 304, X5CrNi18-10)

- 1.4305 – (AISI 303, X8CrNiS18-9)

- 1.4404 – (AISI 316L, X2CrNiMo17-12-2)

- 1.4435 – (AISI 316L, X2CrNiMo18-14-3)

- 1.4571 – (AISI 316Ti, X6CrNiMoTi17-12-2)

Duplex stainless steels:

- 1.4462 – (AISI 318LN, X2CrNiMoN22-5-3)

- 1.4460 – (AISI 329, X3CrNiMoN27-5-2)

Aerospace grades / PH stainless:

- 1.4548 – (AISI 630, 17-4PH, X5CrNiCuNb17-4-4)

- 1.4545 – (15-5 PH, X5CrNiCuNb15-5)

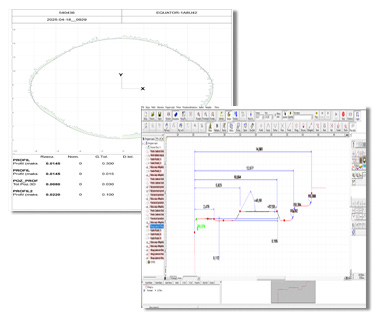

Inspection Reports and Process Plans

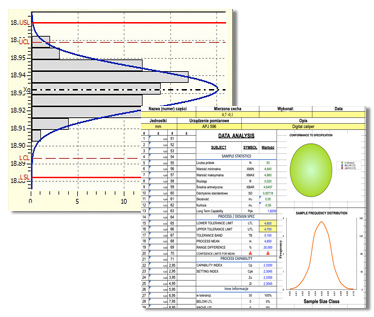

For series CNC production, we prepare comprehensive measurement reports, SPC statistics, and full PPAP or VDA-4 documentation.

Production quality is ensured by a management system compliant with ISO 9001:2015.

Quality Control Plan

A document specifying the sequence of measurements, inspection tools, and inspection frequency at each production stage.

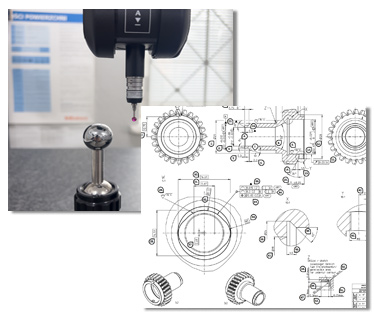

CMM Measurement Report

A summary of measurement results obtained on a coordinate measuring machine (CMM) – including verification of dimensions and geometric errors against the technical documentation.

First Article Inspection Report (FAI)

Documentation confirming the compliance of first manufactured parts with customer specifications – used when launching new projects or implementing process changes.

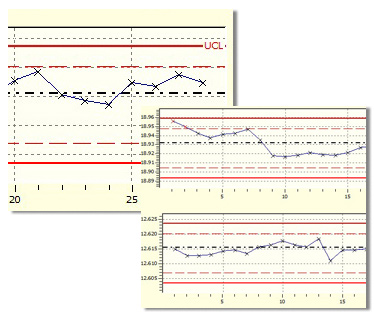

Process Statistics – Cp, Cpk, Pp, Ppk

Statistical indicators for assessing process stability and capability over time. Support quality analysis in series production.

SPC – Statistical Process Control

A method of monitoring production quality by analyzing measurement data. Allows quick response to deviations from nominal values.

MSA – Measurement System Analysis

Assessment of the reliability and repeatability of measuring systems. Used to confirm the credibility of measurement results in quality control.

Additional Finishing Processes and Surface Coating Examples

In cooperation with trusted technological partners, we perform additional surface finishing and protection processes, considering both functionality and appearance.

All processes are executed in accordance with customer documentation and industry standards.

Below we present examples of types of processing and photos from our projects:

Galvanic finishes:

- Anodizing, hard anodizing

- Gold plating, silver plating, tin plating

- Nickel plating, black nickel plating

- Chrome plating

- Zinc plating

Heat / thermo-chemical treatments:

- Nitrocarburizing (e.g. Corr Durr)

- Hardening

- Nitriding

Surface finishing:

- Polishing

- Decorative grinding

Chemical treatments:

- Passivation, Aerospace passivation (AMS2700F Method 1, Type 8, Class 2)

- Electropolishing

- Blackening

Others:

- PVD coatings

- Powder coating (selective)

- Precision grinding

Industries We Serve

We serve clients from various industrial sectors – from high-precision technologies to general mechanical applications.

We manufacture components in line with technical drawings and quality standards, adapting the process to the specific needs of each industry.

Contact with us