CNC Machine Park – APJ Sikora Turning Automatics, Swiss-Type Machines, Machining Centers

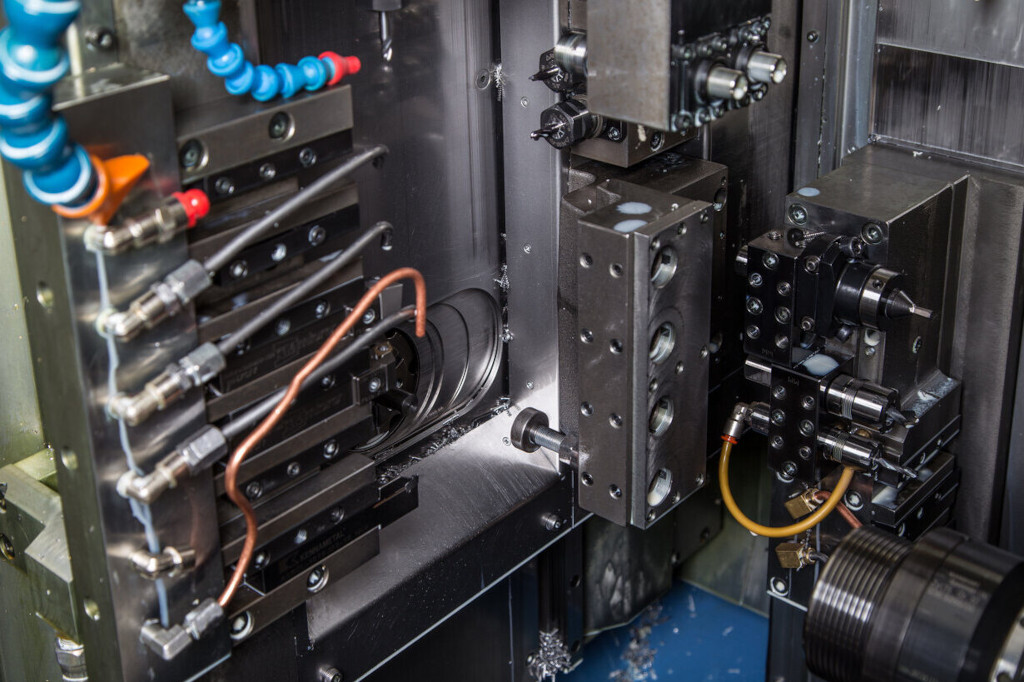

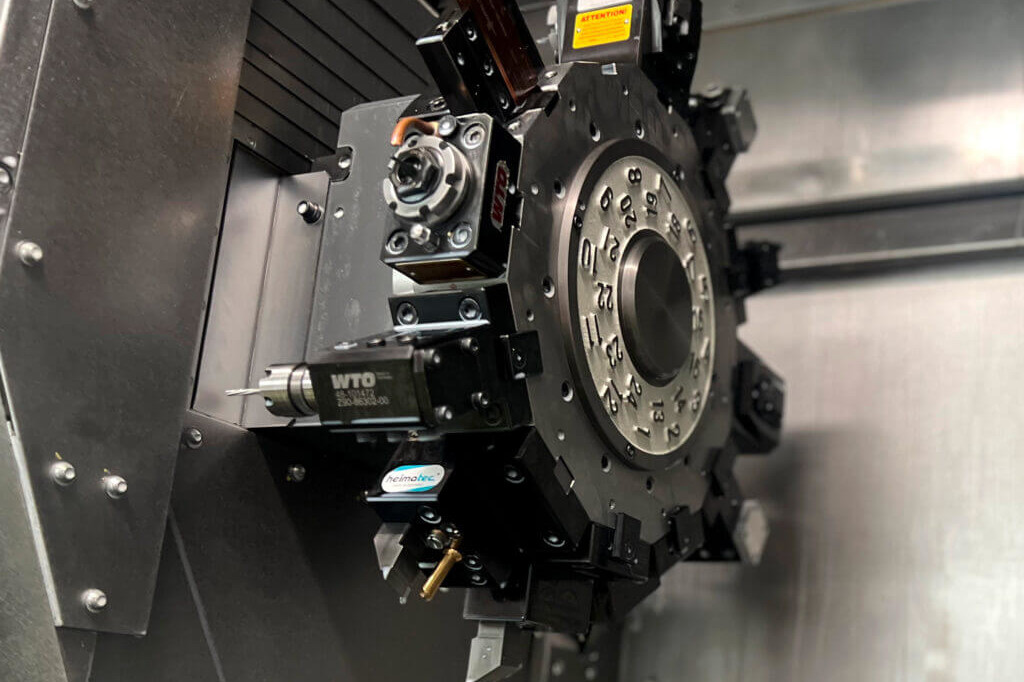

We operate a comprehensive CNC machine park: Doosan and Nakamura turning automatics, Swiss-type machines from Citizen and Tornos, and machining centers with driven tools, enabling us to manufacture complex components in the Ø1–65 mm range.

Thanks to this, we perform CNC turning and milling of precise parts made of aluminum, carbon steel, stainless steel, and brass – from pilot batches to full-scale series production.

CNC Turning Automatics, Swiss-Type Machines, and Machining Centers at APJ Sikora

Our infrastructure includes high-precision CNC turning automatics, versatile machining centers, conventional machine tools, and supporting equipment.

This diversity allows us to carry out series and small-batch production of Ø1–65 mm parts made of aluminum, carbon steel, stainless steel, and brass.

A complete machine park, supported by digital SPC monitoring and a CMM measurement laboratory, ensures stable quality for each production batch and fast changeovers between orders.

Our CNC automatics allow for complex geometry machining in a single setup, which reduces cycle times and lowers production costs.

CNC Machine Tools

We operate modern CNC machining centers with spindle bores up to Ø65 mm and Swiss-type sliding-head automatics with bores up to Ø26 mm, suitable for precise machining of parts with various geometries.

The CNC centers are equipped with driven tools, sub-spindles, bar feeders, and high-pressure units, allowing for efficient deep hole drilling and ensuring repeatability in both series and small-batch production.

Brands we use:

- NAKAMURA

- CITIZEN

- MYIANO

- DOOSAN

- STAR

- TORNOS

- TSUGAMI

Conventional Machine Tools

In addition to modern CNC machines, we also operate a range of conventional machines. We use them where non-standard operations or technological flexibility are required.

- Turning automatics – MAS, SKODA, CEGIELSKI, FATO, GDW

- Drilling and threading machines – IXION, MAXION, FLOTT

Supporting Equipment

To maintain full control over the production process, we also use auxiliary devices for washing, cleaning, deburring, and final surface finishing of components.

- Render C60 spray washer – for fast and effective contamination removal

- Ultron U-1000 ultrasonic washer – for thorough cleaning of hard-to-reach surfaces

- TE30 centrifugal finisher – for smoothing, deburring, and surface preparation

+/- 5µm

Dimensional Precision

since 1928

Market Experience

∅1 - ∅65mm

Manufactured Diameter Range

Industries We Serve

We serve clients from various industrial sectors – from high-precision technologies to general mechanical applications.

We manufacture components in line with technical drawings and quality standards, adapting the process to the specific needs of each industry.

Looking for a Manufacturer with the Right Technological Capabilities?

Our CNC turning machines, supported by conventional machine tools, allow us to carry out even the most demanding projects with repeatability and process control.

Contact us to discuss technical details or inquire about production availability.

Are you curious about the machines we use? Check the manufacturers’ websites: